DESIGN

Solar System specialists develop transformers of various types for use in solar power engineering for all types of solar power plants.

Dry and oil transformers are successfully operating at solar power plants in Ukraine.

The range of transformers has a number of standard models of dry-type transformers .

from 25 to 3150 kVA .

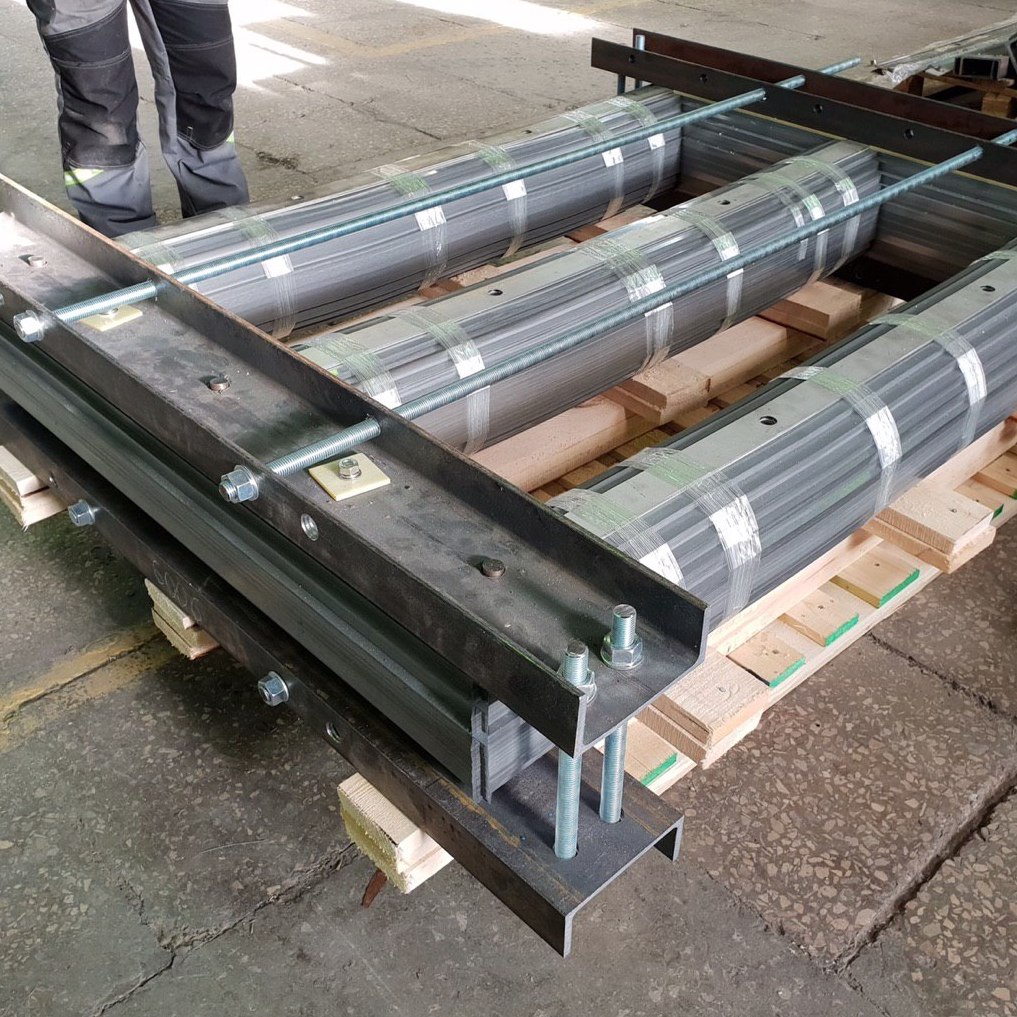

PRODUCTION

Production Solar's special series of cast resin dry-type transformers have exceptional performance in terms of quality standards.

Transformers are intended for the development of technologies for the preservation of the environment.

Production started in 2017.

Temperature

Temperature control of windings is one of the key tasks in the development of any type of transformer equipment. Ensuring reliable and trouble-free operation in any climatic and weather conditions is also the most important task for designers.

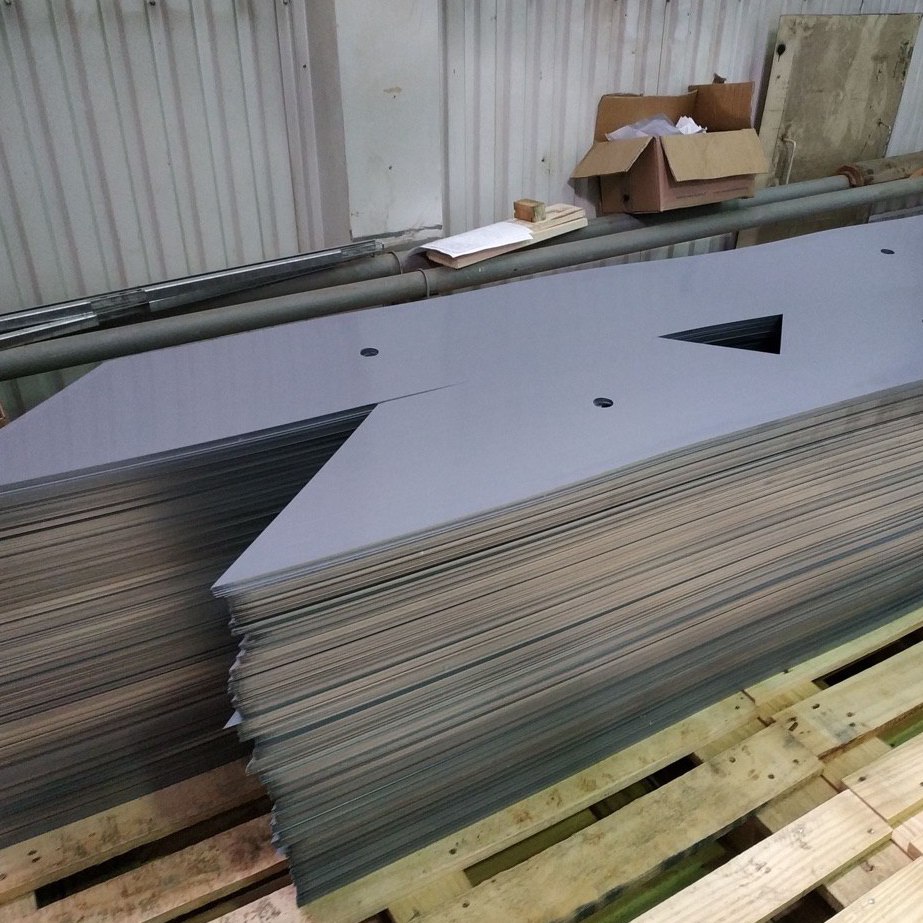

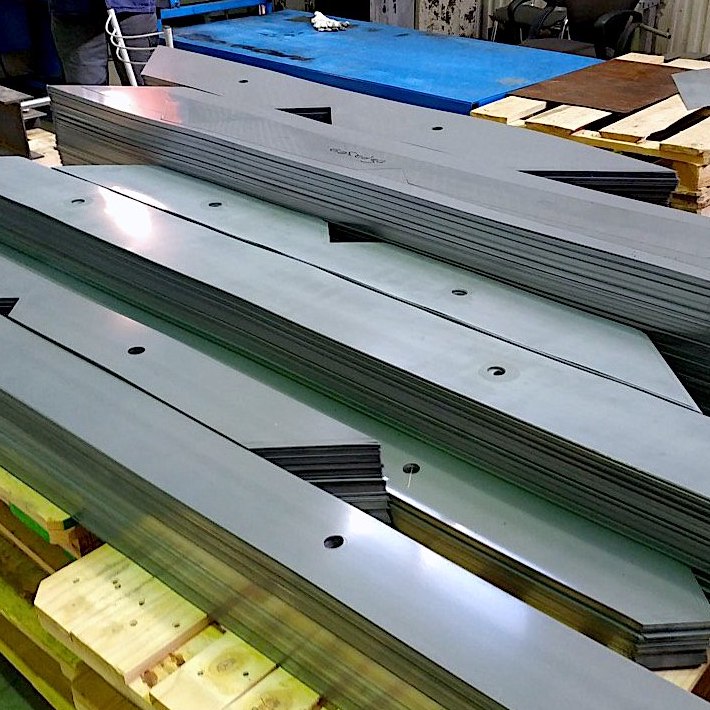

The size

High efficiency with compact dimensions is a benchmark that is constantly present in the development of new transformer equipment of any type, both "dry" and oil-immersed transformers.